SunLink roof mount products — Core RMS and Precision RMS — are specifically designed to compensate for thermal forces and to create a roof friendly interface.

The impact of solar mounting systems on rooftops is a concern for all involved; the designer, developer, installer, and building owner. SunLink has incorporated hundreds of megawatts of rooftop solar experience into an intelligent solution that alleviates these concerns and could eliminate the need for slip sheets. This solution incorporates:

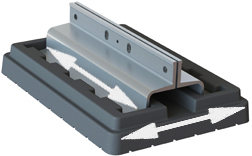

Recycled rubber feet to provide a soft contact surface and prevent any metallic component from contacting the roof.

SunLink’s rail based design, allowing for at least 50% fewer feet on the roof than our competitors’ systems.

Accounting for Environmental Conditions

Through varied project experience across North America, SunLink has encountered extreme environmental conditions; from hurricane force wind loads to record snow loads to severe temperature swings of 50° or more in a 24-hour period.

SunLink roof mount products have been designed to withstand these extreme conditions, and reduce movement due to thermal expansion and contraction in such instances. Specifically:

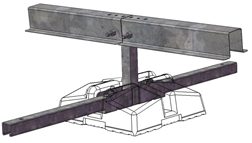

Precision RMS: absorbs expansion and contraction of the system to minimize movement on the roof. The Precision RMS foot bracket is designed to slide inside the recycled rubber foot which isolates motion of the system from the roof.

Core RMS: utilizes oversized connection holes, row and rail link joint flexibility and material composition to absorb the movement on the roof.

译文:

SunLink屋顶安装产品——Core RMS和Precision RMS——专门设计用于补偿热作用力并创建一个适合屋顶的界面。

太阳能安装系统对屋顶的影响是所有相关人员关注的问题;设计者、开发者、安装者和建筑物所有者。SunLink将数百兆瓦的屋顶太阳能体验整合到一个智能解决方案中,缓解了这些担忧,并可以消除对滑片的需求。该解决方案包括:

再生橡胶脚提供柔软的接触面,防止任何金属部件接触屋顶。

SunLink基于轨道的设计,与竞争对手的系统相比,屋顶上的英尺数至少减少了50%。

通过北美不同的项目经验,SunLink遇到了极端的环境条件;从飓风风力荷载到记录雪荷载,再到24小时内50°或以上的剧烈温度波动。

SunLink车顶安装产品的设计能够承受这些极端条件,并在这种情况下减少因热膨胀和收缩引起的移动。明确地:

精密RMS:吸收系统的膨胀和收缩,以最小化屋顶上的移动。Precision RMS支脚支架设计用于在回收的橡胶支脚内滑动,从而将系统运动与车顶隔离。

核心RMS:利用超大连接孔、排和轨道连接接头灵活性和材料组成吸收屋顶上的运动。