安装太阳能屋顶的附件都需要通过屋面材料钻洞数十种,使车顶任何易受水的侵入。鉴于这一现实,理解重要的是如何侵入水(及由此产生的建筑损伤)发生和安装方式可以阻止它的发生。

不当防水屋顶太阳能系统是昂贵的。劳动力成本来修复较小的泄漏往往在$ 500千美元范围。如果问题较大,亮出坐骑或整个屋顶可能需要更换。光伏系统“删除并重新安装”(通常被称为“R&R”)从50美分/瓦的成本上升至1.50美元/瓦取决于屋顶的类型和阵列配置。这相当于高达20%至40%的新光伏系统的价格。

之前我们谈论的防水,我们需要解决的屋顶检查。瓦寿命一般为15到30年,且同样适用于瓦垫层。破裂或卷曲带状疱疹或垫层是一个强烈的信号,该屋顶是超越中年。如果屋顶是超过5到10岁,太阳能安装应建议更换屋顶的客户,因为它是一个明智的投资。在较旧的屋顶上安装可以是不可取的在某些情况下,但另一种选择是reroofing仅在将要获得的太阳能屋顶的一部分。

屋顶的水管理基础

两个基本策略消除了对屋顶漏水的风险存在:“分水”,“防水性能”和

屋顶低于2:12(低坡屋顶)的间距将使用防水膜。这两种常见的类型是沥青“建成,屋顶”或塑料或橡胶片制成“单层膜”。防水卷材工作通过密封接缝每个,裂纹和缝隙。这种屋面方法导致水密膜保护在最重的降雨,即使当积水时,为20至30年。这些屋面系统需要一个合格的盖屋顶的密封每渗透,采取非常谨慎的长期可靠性。一年两次的检查和维修由合格盖屋顶都需要保持最卷材屋面的保证。

与防水卷材,分水系统,如瓷砖和沥青瓦依靠屋顶防水效果的陡度。带状疱疹是最有效的,当屋顶有一个陡峭的间距和他们在低坡屋顶的效果较差。当屋面坡度低于4:12,都需要特殊的防水措施,包括完全遵守垫层。

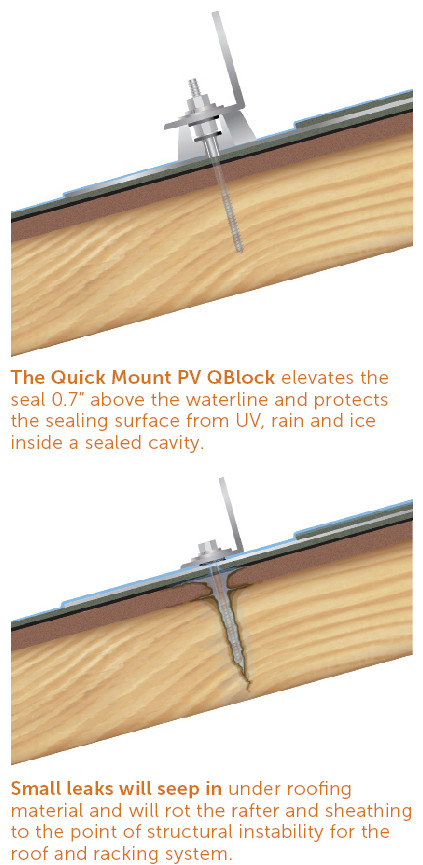

水如何进入

流行的看法相反,雨水总是不流动下坡。风吹水可达瓦或瓷砖之间,和毛细管作用将水侧身,甚至上坡。当水发现即使是最小的针孔,其屋面渗漏下。随着时间的推移它浸泡腐烂和护套和椽子,导致结构破坏,削弱附件和模具可能形成。较大的孔会导致损坏发生的更迅速。这是建筑规范和屋顶制造商授权使用下面的水脱落的屋顶垫层,并要求屋面制造商认可的闪烁都贯穿的原因。

选择适当的方法闪烁

像TPO,PVC和EPDM单层膜使用热或化学焊接泛而火炬向下泛上建成的沥青屋顶常态。大多数屋顶制造商需要一个合格的盖屋顶进行安装闪烁维护保修。这通常意味着持牌盖屋顶安装会低坡度泛水。像造粒轧制屋面一些膜可以通过太阳能承包商与较新的闪烁系统中,如密封剂音调口袋或纤维增强的聚合物膜泛水进行安装。

选择适当的金属对瓦或瓦片屋顶泛水是生命闪烁的很严格。抗腐蚀材料,如铝是首选,因为它可以持续30年以上。镀锌钢板可能只可靠为10到15年,这取决于气候。在潮湿的气候,腐蚀性沿海的条件下,太阳能安装往往选择较厚的金属闪光打击频繁的风动雨或盐雾的影响。

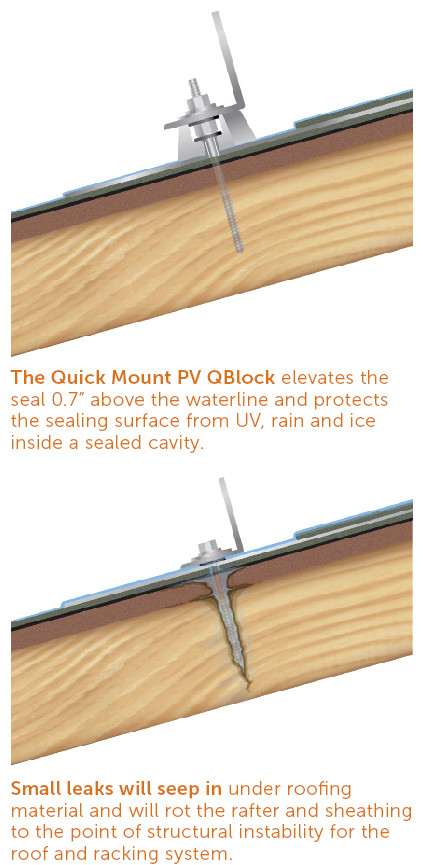

提升防水密封

水密封表面是针对雨水下闪蒸并进入渗透得到的关键障碍。提升这个关键障碍是关键要素,可靠,长期防水之一。在低斜率屋顶,这是通过密封闪烁向膜和升降以上洪水线的密封区域的基地完成。在陡峭的坡屋顶,提升水封具有重大优势。首先,它减慢的橡胶密封件的恶化,因为它减少暴露于水,并且该密封变干速度,防止恶化从生物生长。另外,冰形成的冷冻气候可以穿出来,通过连续的冻融循环的印章。高温密封减少或消除冰接触的密封。

这个屋顶的护套是从严重岭附近泄漏染色。护套和椽子会削弱随着时间的推移,可能需要更换。

这个屋顶的护套是从严重岭附近泄漏染色。护套和椽子会削弱随着时间的推移,可能需要更换。

密封胶注意事项

密封剂通过本身具有差的长期防水可靠性,同时结合使用制造商核准的闪烁的方法时,它可以提供几十年的可靠的性能。密封剂通常应用到所有的导向孔和周围的滞后螺栓孔的闪烁下。

有在屋顶的太阳能发电装置使用了几种常见的密封剂,并且它是非常重要的验证密封剂是相容的屋面,闪烁密封和任何其它材料它们接触。

沥青屋面水泥(乳香)与增强网是用于密封衬垫防雨板下面瓦片的码批准的方法,而且它也用作密封剂上的带状疱疹,但是大多数太阳能安装依靠屋面密封剂像从Chemlink和Geocel。这些合成密封胶可提供数十年的性能,当正确应用。每个密封胶是在其性能特点是独一无二的。一些密封剂能治水下,而另一些人喜欢干的应用。有些可以处理温度超过200°F,而其他不应该与充足的阳光照射的区域使用。研究是重要的,以确保密封胶可以持续在屋顶和阵列的寿命。

适当的防水并不总是方便快捷。鼓励太阳能安装以获得对屋面系统和防水方法,适当的教育。这可能需要一段时间来掌握闪烁安装的精妙之处,但那些作出努力,将与穿透了屋顶的生命和太阳系可靠的防水予以奖励。

本文由杰夫提供,快速安装光伏公司 高级主管贡献。

原文

Installing solar roof attachments requires drilling dozens of holes through roofing material, making any roof vulnerable to water intrusion. Given this reality, it’s important to understand how water intrusion (and the resulting building damage) occurs and ways installers can prevent it from happening.

Improperly waterproofing a rooftop solar system is expensive. The labor costs to repair smaller leaks often range between $500 and $1,000. If the problem is bigger, flashed mounts or the whole roof may need replaced. A PV system “remove and reinstall” (often referred to as “R&R”) costs from 50¢/watt up to $1.50/watt depending on roof type and array configuration. This equates to a whopping 20 to 40% of the price of a new PV system.

Before we talk about waterproofing, we need to address roof inspection. Shingle life typically ranges from 15 to 30 years, and the same is true for tile underlayment. Cracked or curling shingles or underlayment is a strong indicator that the roof is beyond middle age. If the roof is more than five to 10 years old, solar installers should recommend roof replacement to customers, as it is a sensible investment. Installing on older roofs may be inadvisable in some cases, but another option is reroofing only on the part of the roof that will be getting solar.

Rooftop water management basics

Two basic strategies exist for eliminating the risk of leaks on roofs: “water-proofing” and “water-shedding.”

Roofs with a pitch below 2:12 (low-slope roofs) will use waterproofing membranes. The two common types are asphaltic “built-up-roofing” or “single ply membranes” made from plastic or rubber sheets. Waterproof membranes work by sealing every seam, crack and crevice. This roofing method results in a watertight membrane that protects in the heaviest rains, even when ponding occurs, for 20 to 30 years. These roofing systems require a qualified roofer to seal every penetration, taking great care for long-term reliability. Biannual inspection and service by a qualified roofer are required to maintain most membrane roof warranties.

Unlike waterproofing membranes, water-shedding systems like tile and asphalt shingles rely on the steepness of the roof for effective waterproofing. Shingles are most effective when the roof has a steeper pitch and they are less effective on lower slope roofs. When the roof pitch goes below 4:12, special waterproofing measures are required, including fully adhered underlayment.

How water gets in

How water gets in

Contrary to popular belief, rainwater does not always flow downhill. Wind blows water up between shingles or tile, and capillary action draws water sideways and even uphill. When water finds even the smallest pinhole, it seeps under the roofing. Over time it soaks and rots the sheathing and rafters, leading to structural damage, weakened attachments and possible mold formation. Larger holes will result in damage occurring more quickly. This is the reason that building codes and roofing manufacturers mandate the use of underlayments below water shedding roofs and require roofing manufacturer-approved flashing for all penetrations.

Choosing proper flashing methods

Single ply membranes like TPO, PVC and EPDM use thermally or chemically welded flashings while torch-down flashings are the norm on built-up asphalt roofs. Most roofing manufacturers require that a qualified roofer perform flashing installation to preserve the warranty. This typically means a licensed roofer would install low slope flashings. Some membranes like granulated rolled roofing may be installed by solar contractors with newer flashing systems, such as sealant pitch pockets or fabric-reinforced polymeric membrane flashings.

Choosing the proper metal for flashings on shingle or tile roofs is critical to the long life of the flashing. A corrosion-resistant material like aluminum is preferred because it can last more than 30 years. Galvanized steel may only be reliable for 10 to 15 years, depending on the climate. In wet climates or corrosive coastal conditions, solar installers often choose thicker flashing metal to combat the effects of frequent wind-driven rain or salt spray.

Elevating the waterproofing seal

The water sealing surface is the critical barrier against rainwater getting under the flashing and into a penetration. Elevating this critical barrier is one of the key elements to reliable, long-term waterproofing. On low-slope roofs, this is accomplished by sealing the base of the flashing to the membrane and elevating the sealing area above the flood line. On steep-slope roofs, elevating the water seal has major advantages. First, it slows down the deterioration of the rubber seal as it reduces water exposure, and the seal dries out faster, preventing deterioration from biological growth. Additionally, ice formation in freezing climates can wear out the seal through successive freeze-thaw cycles. An elevated seal reduces or eliminates ice contacting the seal.

The sheathing of this roof is badly stained from leaks near the ridge. The sheathing and rafters will weaken over time and may need to be replaced.

Sealant considerations

Sealant by itself has poor long-term waterproofing reliability, but when used in combination with manufacturer-approved flashing methods it can provide decades of reliable performance. Sealant is typically applied into all pilot holes and under the flashing around the lag bolt hole.

There are several common sealants used in rooftop solar installations, and it is crucial to verify sealants are compatible with the roofing, flashing seal and any other materials they contact.

Asphaltic roofing cement (mastic) with reinforcing mesh is a code approved method for sealing underlayment flashings below tile, and it is also used as sealant on shingles, but most solar installers rely on roofing sealants like those from Chemlink and Geocel. These synthetic sealants can provide decades of performance when properly applied. Each sealant is unique in its performance characteristics. Some sealants can cure underwater while others prefer dry application. Some can handle temperatures over 200°F while others should never be used in areas with full sun exposure. Research is important to make sure the sealant can last the life of the roof and array.

Proper waterproofing is not always quick and easy. Solar installers are encouraged to get proper education on roofing systems and waterproofing methods. It can take time to master the subtleties of flashing installation but those that make the effort will be rewarded with reliable waterproofing on penetrations for the life of the roof and the solar system.

This article was contributed by Jeff Spies, senior director of policy for Quick Mount PV.