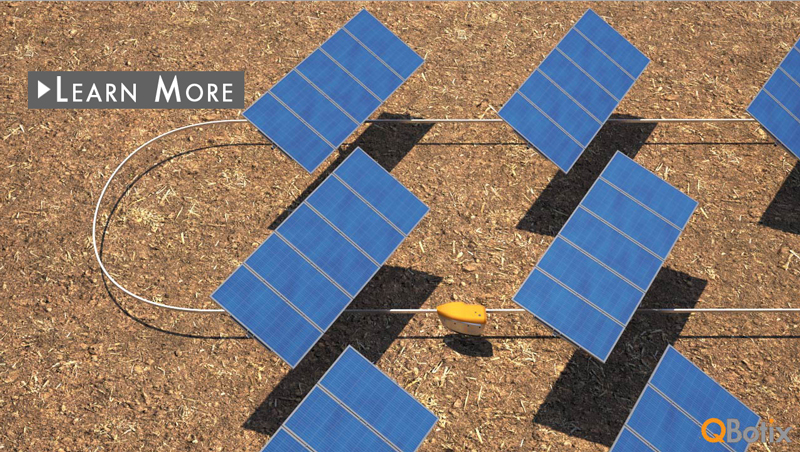

Based on our paradigm of Solar Robotics™, the Robotic Tracking System™ (RTS) fundamentally re-invents the design of all solar tracking systems. Click the video below to learn more.

Conventional tracking systems use metal and concrete materials in sub-optimal fashion. The result is massive and expensive systems that are failure prone and difficult to install. Typically, the material content of all tracking systems is two to three times higher than fixed-tilt systems. The fundamental reason for sub-optimal material utilization is due to the desire to have each actuation and control system track many panels that collectively comprise a large surface area. The alternative is having motors and control systems for many small trackers, which results in significant actuation costs and low reliability.

We approach the problem with a completely fresh approach. We began by designing a tracking system that was optimized in terms of material utilization and that would provide the strength, robustness and reliability needed over the 20 plus year life of the solar project. Then we solved the underlying system-level actuation and controls requirement through our paradigm of Solar Robotics™.

The RTS employs a pair of autonomous, mobile robots to control up to 340 kW of solar modules with high accuracy, reliability, and 100% redundancy. The solar modules are installed on the QBotix designed trackers without individual motors and are optimized for cost, strength, durability, and installation simplicity. The robots travel on a rail and adjust each tracker periodically to optimally face the sun.

This allows us to create a tracker optimized for material usage, reliability, ease of installation, and maximized production.

Each rugged robot replaces hundreds of individual motors and controllers found on conventional tracking systems. In addition, the use of two robots per block or loop provides built in system redundancy. This improves the system reliability and ensures high availability of tracking capability.

The embedded intelligence and data communication capabilities of each autonomous robot enable both optimized power plant performance and detailed operational knowledge at an unprecedented level.

根据我们的太阳能机器人™的范式,机器人跟踪系统™ ( RTS )从根本上重新发明了所有的太阳能跟踪系统的设计。点击下面的视频了解更多信息。

常规的跟踪系统使用的金属和混凝土材料在亚最佳方式。结果是大量的和昂贵的系统,是易出故障且难以安装。通常情况下,所有的追踪系统的材料的含量比固定倾斜系统高出两到三倍。其根本原因是次优的材料利用率是由于让每个驱动及控制系统跟踪许多板,它们共同组成一个大的表面积的愿望。另一种是有电机和控制系统对于许多小型跟踪器,从而导致显著驱动成本和可靠性低。

我们处理这个问题有一个完全新鲜的做法。我们开始通过设计进行了优化,在材料利用方面,并会提供所需的超过20年,加上生活中的太阳能项目的强度,耐用性和可靠性的跟踪系统。然后,我们解决了通过我们的太阳能机器人™的范式基础的系统级驱动和控制要求。

垃圾转运站采用了一对自主移动机器人控制高达340千瓦具有精度高,可靠性,和100 %的冗余太阳能电池组件。太阳能电池组件安装在QBotix设计跟踪而不各个电机和成本,强度,耐久性,和安装简单的优化。机器人行驶在轨道上,并定期调整每个跟踪到最佳面对太阳。

这使我们能够创建材料的使用,可靠性,安装方便,并最大化生产优化的跟踪器。

每一个崎岖的机器人取代了数百个独立的电机和控制器的常规跟踪系统发现。此外,使用每块或环两个机器人提供了内置在系统冗余。这提高了系统的可靠性,并确保跟踪能力的高可用性。

每个自治机器人的嵌入式智能和数据通信能力,在一个前所未有的水平同时启用优化电厂性能和详细的操作知识。

查看Robotic Tracking System™ 太阳能跟踪机器人系统简介:

QBotix_RTS_Spec_Sheet_Oct_2013