获取更好的能量收获及投资回报最大化是公用事业规模太阳能电站业主和开发商的首要目标。

今天,重点转移到定向向着太阳光伏板,以全天-作为一个可靠的手段来实现这些目标收集更多的阳光直射太阳能跟踪机动结构。据分析公司IHS最近的一份研究报告显示,单轴跟踪器将系统地安装结构为今年在美国的光伏组件平衡的首选类型。的确,单轴跟踪器增加植物产量高达25%相比,固定倾斜安装。

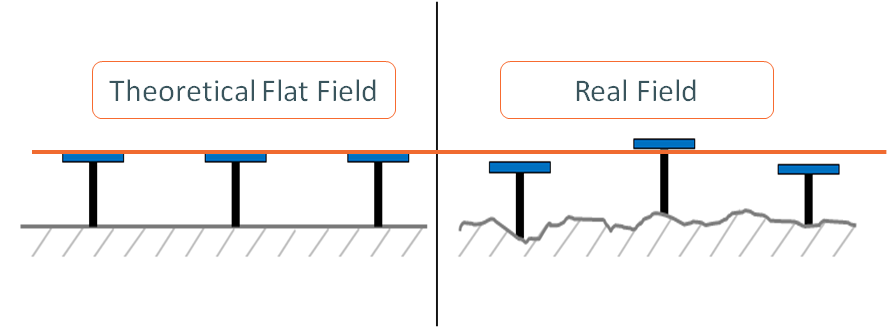

配备有单轴跟踪器的太阳能设备的能量输出可以通过实施高效的跟踪处理得到进一步的优化。基本产量计算,考虑一个完全平坦的地形。但是没有字段是完全平坦的。斜坡和地形不规则产生,应正确预计产量损失。太阳能跟踪专家Exosun考虑到了那些变化地形和开发SMARTracking,智能专利两步跟踪过程来解决的非平面场的影响,并产生高达5%,每年额外收率,相对于其他基本的解决方案。让我们来看看它是如何工作的。

在设计研究阶段抵消土地的不良情况:第1步

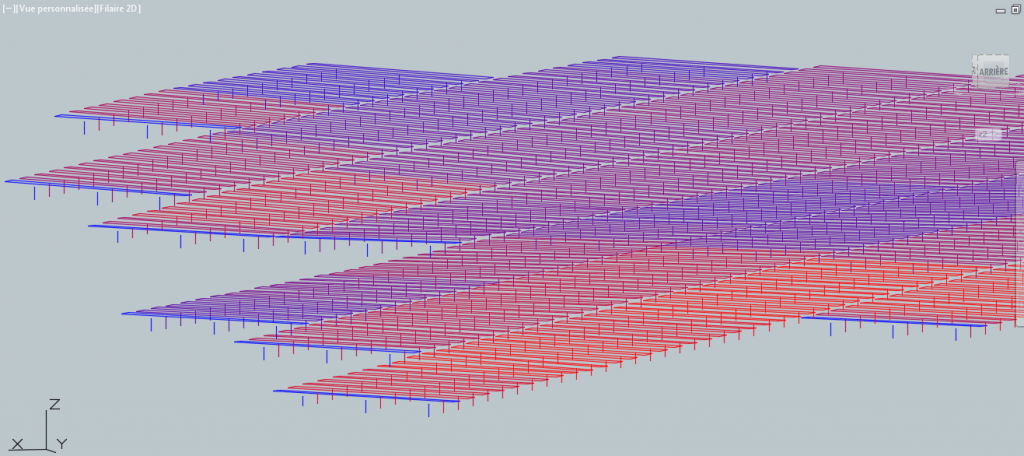

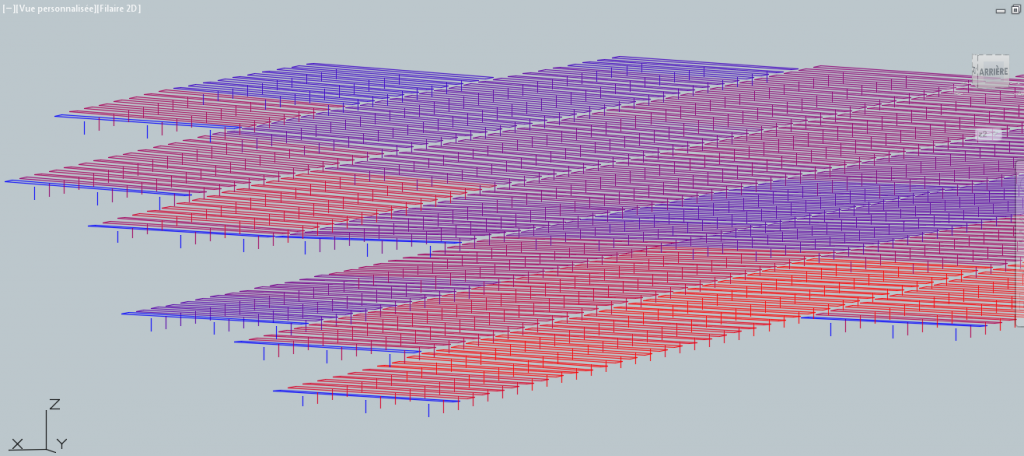

该方法的第一步包括的工厂布局在项目的设计研究阶段的三维优化。之前进行植物的3D研究中,一个二维工厂布局是根据工厂的现场边界的形状创建和优化。

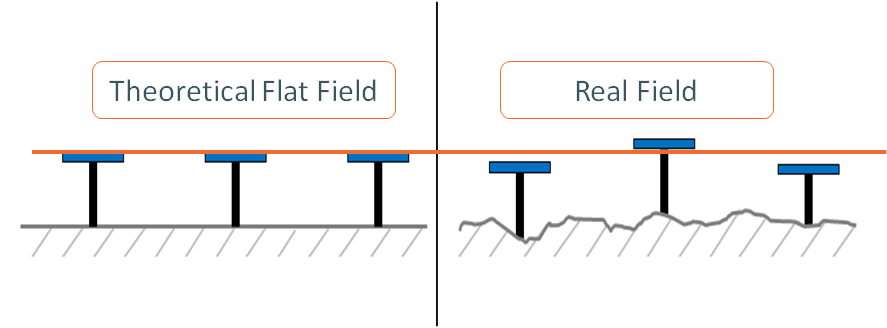

该3D优化开始与地形的详细地形分析。它允许确定在为了平滑太阳能电池组件的表面上的植物尽可能并减少了对分级每个跟踪桩的完美高度。因此,表之间的相互遮蔽被减少,从而减少回溯周期和优化能源产量。此外,它也避免了在现场桩切割。

该研究导致产生一个桩小册子,其中每个跟踪桩上的植物的三维定位所注册的文档。

第2步:在施工阶段,实现个人跟踪

一旦桩在施工阶段的开始驱动,其真正的现场定位,并收集在一个文档中注册的,称为建成的调查。个人跟踪程序,然后开发并实现了基于注册的价值。这个程序对应于每个电动机控制单元,其包括回溯(面板上面板避荫)策略中一个自定义例程。

跟踪算法,在中央PLC实现,实时计算和为每一个电机的优化角度。这个角度是根据一个特定的跟踪者和其邻国的表的精确位置来确定。

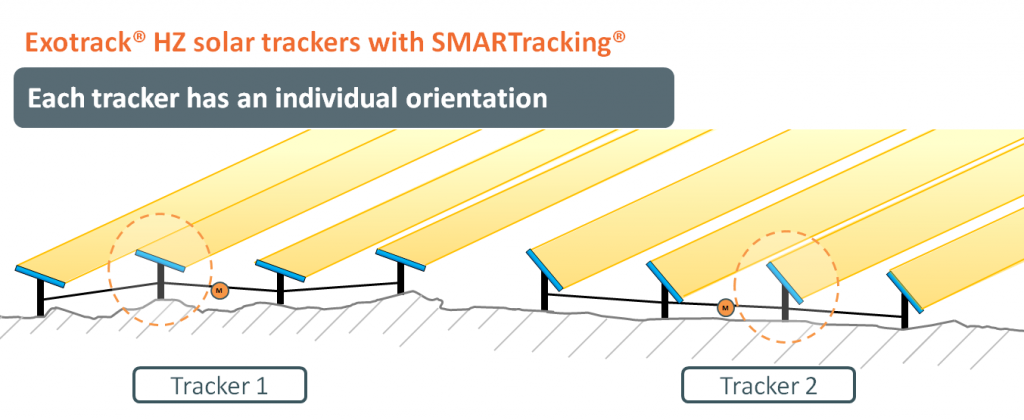

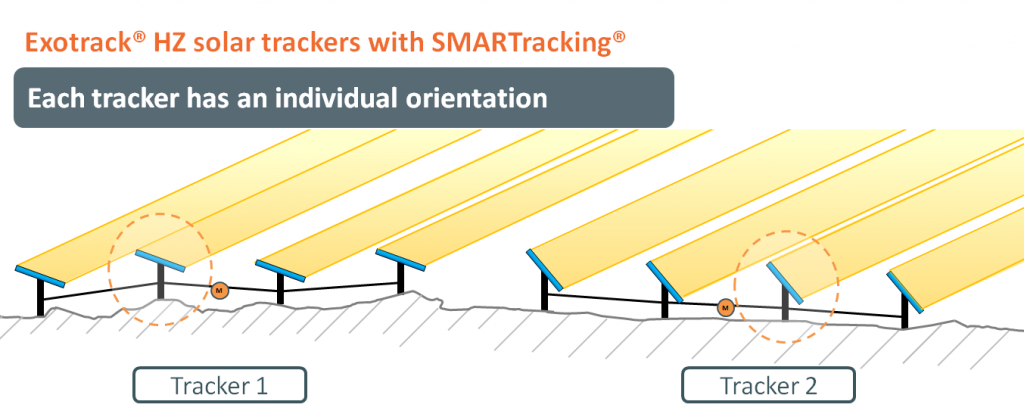

图像的两个跟踪器的各个运动学3例。 (橙色圆圈表示的临界表定义跟踪器的跟踪角)

每个太阳能跟踪器具有在一天中的任何时刻,在最适合的位置和它的控制是个性化的,从而最大程度地接收照射,提高能源生产相比,全球回溯的方法。

更重要的是,已建成的调查是依据初始桩小册子和成堆的真实现场定位之间的差距分析。此研究的目的是检测出任何默认可能导致安装不可能,从而避免时间潜在损失。

SMARTracking是这两个步骤的过程,每一个导致特定能量增益的结果。该两个步骤是彼此独立的。

案例分析:SMARTracking在6.7兆瓦光伏电站项目在法国:一个5%的额外增益生产

现在,让我们把真实人物的生产和收入增长在这方面的专利两步跟踪过程通过查看位于法国西南部一个6.7兆瓦的光伏电站项目。

下表总结了项目数据。

选址:法国西南部

工厂的生产能力:6.7兆瓦

Exotrack数:HZ单轴太阳能跟踪器48

全年发电量:8750兆瓦时/年

光伏组件:72C型单晶315 Wp的

下文表格表示与现场地形数据。

当地山坡南坡东坡北/东斜坡南/东斜坡

最小-4.02%-6.45%-4.39%-4.75%

最高4.58%7.51%5.78%6.46%

平均1.21%1.34%1.15%1.28%

通过实施SMARTracking工艺上配备了Exotrack HZ单轴跟踪器这一光伏电站,额外的5%,产量增加了,每年实现的。这导致美元88万的收入增长超过20年的基础上,100 $ /兆瓦时PPA。下面的结果由一个独立的技术咨询公司,kiloWattsol进行了验证。

生产与收益照射SMARTracking生产获得收益

第1步:三维工厂布局优化1.8%2.1%(185兆瓦时/年)

步骤2.个人跟踪2.5%,2.9%(255兆瓦时/年)

SMARTracking(步骤1步骤2)4.3%5%(440兆瓦/年)

收入增长与SMARTracking PPA例如1 PPA例如2

PPA 100 $ /兆瓦时80€/兆瓦时62 $ /兆瓦时50€/兆瓦时

每年的收入增长得益于SMARTracking44000美元35 000€27125美元21 875€

通过SMARTracking超过20年880000美元700 000€542000美元437 000€产生的收入增长

这篇文章是由洛朗Sarrade,在Exosun全球产品经理。其主打产品是友好的LCOE水平单轴跟踪器Exotrack HZ。随着土地定级需求减少,这种创新的追踪系统设计用于快速和简便的安装,简化直流电缆管理和最小的OPEX。其独特的集中控制系统可以驾驶多达纤夫的8兆瓦。高度可靠和稳定的,Exotrack HZ是一个真正的收入助推器公用事业规模太阳能电站业主和开发商。

原文:

Obtaining better energy harvest and maximizing return on investment are the primary goals for utility-scale solar plant owners and developers.

Today, focus is shifting to solar trackers–motorized structures that orient photovoltaic panels toward the sun in order to collect more direct sunlight throughout the day–as a reliable means to achieve these objectives. According to a recent research report by analyst firm IHS, single-axis trackers will be the preferred type of balance of system ground-mounted structure for PV modules in the USA this year. Indeed, single-axis trackers increase plant production up to 25% in comparison to fixed-tilt installations.

The energy output of a solar plant equipped with single-axis trackers can be further optimized by implementing an efficient tracking process. Basic yield calculations consider a perfectly flat terrain. However no field is completely flat. Slopes and terrain irregularities generate production losses that should be correctly anticipated. Solar tracking expert Exosun took into account those variations in the terrain and developed SMARTracking, an intelligent patented two-step tracking process to address the impact of non flat fields and generate up to 5% additional yield annually, compared to other basic solutions. Let’s take a look at how it works.

Step 1: Offsetting land irregularities during the design study phase

The first step of this process consists of a three-dimensional optimization of the plant layout at the design study phase of the project. Prior to carrying out a 3D study of the plant, a 2D plant layout is created and optimized according to the shape of the plant’s site borders.

The 3D optimization starts with a detailed topographic analysis of the terrain. It allows to determine the perfect height of each tracker pile in order to smooth the surface of the solar modules on the plant as much as possible and to reduce the need for grading. Consequently, mutual shading between tables is reduced, thereby reducing backtracking periods and optimizing the energy yield. In addition, it also avoids on-site piles cutting.

Image 1: piles optimization and surface smoothing

This study results in the creation of a piles booklet, a document in which the three dimensional positioning of each tracker pile on the plant is registered.

Image 2: example of a 3D layout with several solar trackers

Step 2: Implementing individual tracking during the construction phase

Once the piles are driven at the beginning of the construction phase, their real on-site positioning is collected and registered in a document, called as-built survey. The individual tracking program is then developed and implemented based on the registered values. This program corresponds to a custom routine within each motor control unit that includes a backtracking (panel on panel shade avoidance) strategy.

The tracking algorithm, implemented in the centralized PLC, calculates the optimized angle in real time and for every single motor. This angle is determined according to the exact location of the tables of a particular tracker and its neighbors.

Image 3. Example of the individual kinematics of two trackers.

(the orange circles indicate the critical table that defines the tracking angle of the tracker)

Each solar tracker has the best suited position at any moment of the day and its control is individualized, which maximizes received irradiation and improves the energy production compared to a global backtracking approach.

What’s more, the as-built survey is the basis for a gap analysis between the initial piles booklet and the real on-site positioning of the piles. This study aims to detect any default that could result in a mounting impossibility, thus avoiding potential loss of time.

SMARTracking is the result of this two-step process, each one leading to specific energy gains. The two steps are independent from each other.

Case study: SMARTracking on a 6.7-MWp PV plant project in France: a 5% additional production gain

Let’s now put real figures in terms of production and revenue gains on this patented two-step tracking process by looking at a 6.7-MWp PV plant project situated in South West France.

The below table summarizes the project data.

| Site location | South West France |

| Plant capacity | 6.7 MWp |

| Number of Exotrack HZ single-axis solar trackers | 48 |

| Annual energy yield | 8750 MWh/year |

| PV modules type | 72c Monocrystalline 315 Wp |

The table hereunder indicates the data related to the site topography.

| Local slopes | South Slope | East Slope | North/East Slope | South/East Slope |

| Minimum | -4.02% | -6.45% | -4.39% | -4.75% |

| Maximum | 4.58% | 7.51% | 5.78% | 6.46% |

| Average | 1.21% | 1.34% | 1.15% | 1.28% |

By implementing the SMARTracking process on this PV plant equipped with Exotrack HZ single-axis trackers, an additional 5% yield increase was achieved annually. This results in a revenue increase of $880,000 over 20 years, based on a PPA of 100 $/MWh. The below results were validated by an independent technical advisory firm, kiloWattsol.

| Production gains with SMARTracking | Irradiation gains | Production gains |

| Step 1. 3D Plant Layout Optimization | 1.8% | 2.1% (185 MWh/year) |

| Step 2. Individual tracking | 2.5% | 2.9% (255 MWh/year) |

| SMARTracking (step 1 & step 2) | 4.3% | 5% (440 MWh/year) |

| Revenue gains with SMARTracking | PPA example 1 | PPA example 2 | ||

| PPA | 100 $/MWh | 80 €/MWh | 62 $/MWh | 50 €/MWh |

| Yearly revenue increase thanks to SMARTracking | $44,000 | 35 000 € | $27,125 | 21 875 € |

| Revenue increase generated by SMARTracking over 20 years | $880,000 | 700 000 € | $542,000 | 437 000 € |

This article was written by Laurent Sarrade, global product manager at Exosun. Its flagship product is the LCOE friendly horizontal single-axis tracker Exotrack HZ. With a reduced need for land grading, this innovative tracking system has been designed for fast and simple installation, simplified DC cable management and minimal OPEX. Its unique centralized control system can pilot up to 8 MWp of trackers. Highly reliable and robust, Exotrack HZ is a genuine revenue booster for utility-scale solar plant owners and developers.